AUTHOR : admin FROM : 未知ADD TIME : 2019-10-15 11:42 HITS : BELONG : INDUSTRY NEWS

Can nylon filter bags be used as filter bags in the food industry?

What are the advantages and disadvantages

In answering this question, we will learn a little about the characteristics of nylon and decide whether nylon filter bags can be used in the food industry.

First of all, nylon is developed by Carothers, an outstanding scientist in the United States, and a research team under his leadership. It is the first synthetic fiber in the world. Nylon is a term for polyamide fibers.

The appearance of nylon has brought a new look to textiles. Its synthesis is a major breakthrough in synthetic fiber industry and a very important milestone in polymer chemistry.

The nylon used in nylon filter bags has good comprehensive properties, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication, and low friction coefficient.

It has certain flame retardancy and is easy to process. It is suitable for filling and reinforcing with glass fibers and other fillers to improve performance and expand application scope.

In addition, nylon filter bags have good cleaning and anti-fouling properties, which are affected by the cross-section shape of the fibers and the anti-fouling treatment of the back passage.

The strength and hardness of nylon fibers have little effect on cleaning and anti-fouling.

We're looking back at nylon filter bags.

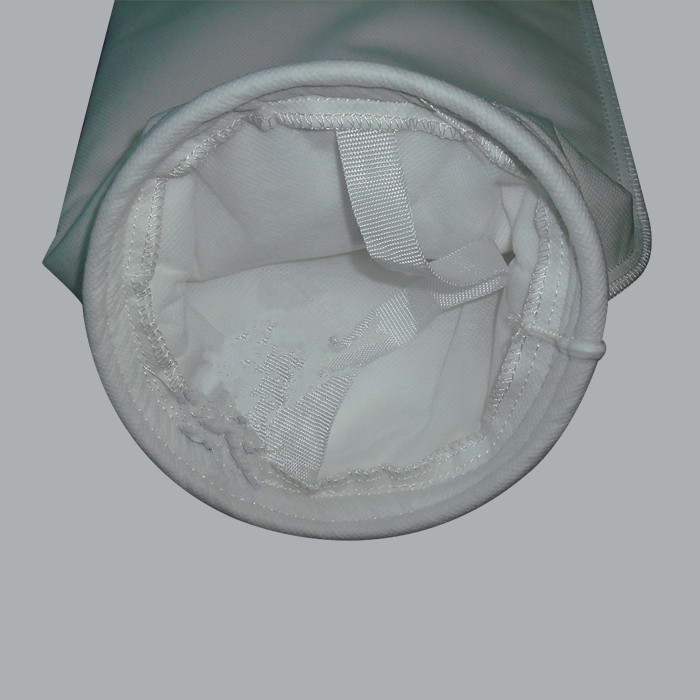

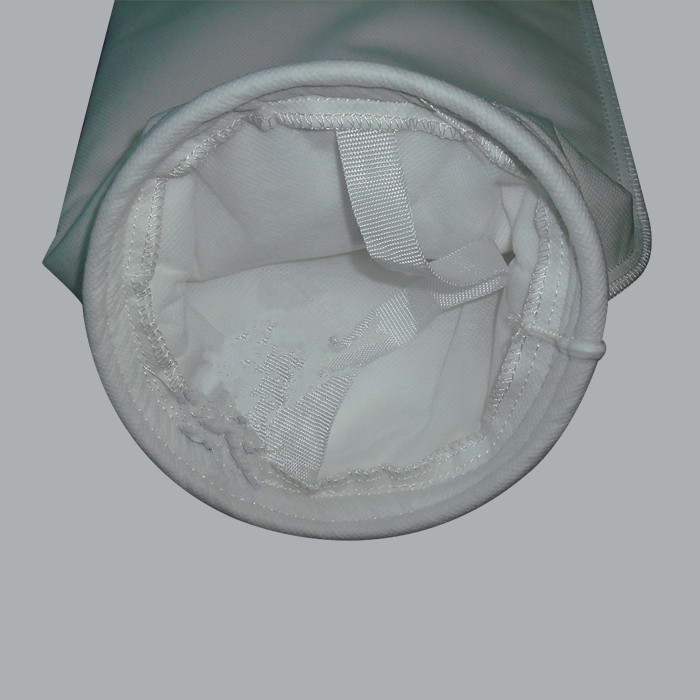

Nylon filter bags are made of high strength nylon woven mesh sewing, and all of them adopt unique edge-wrapping technology to prevent needle hole leakage to the greatest extent,

and retain impurities larger than their own mesh directly on the surface of the material.

Particles smaller than the mesh diameter enter the downstream through the mesh, so nylon monofilament filter bags achieve surface filtration, smooth surface is also easy to clean, can be used repeatedly.

The advantages of nylon filter bag are as follows:

1. High-speed industrial sewing machine without silicone oil cooling will not produce filter bags with silicone oil pollution.

2. The improved suture of nylon filter bag mouth has no high protuberance, which leads to side leak without needle eye and leads to side leak.

3. All the labels on nylon filter bags marked with product specifications and models are easy to remove, so as to prevent the pollution of filter bags by labels and ink in use.

4. The filter precision ranges from 0.5 micron to 300 micron. The material is divided into polyester, polypropylene nylon and other filter bags.

5. Argon arc welding technology for stainless steel and galvanized steel ring. The diameter error is only less than 0.5 mm and the horizontal error is less than 0.2 mm.

The filter bag made of this kind of steel ring can be installed in the equipment to improve the sealing degree and reduce the probability of side leakage.

Advantages of Nylon Filter Bag - Recommended Precision:

In food and beverage industry, 80 mesh to 350 mesh nylon filter bags are recommended; in chemical industry, 80 mesh to 150 mesh nylon filter bags are recommended.

Nylon Filter Bag - Size Specification:

Size Name of Filter Bag Maximum Flow (Water) m3/h Filtration Area () Volume (L) Diameter mm Length mm Matching Filter Name

No.1 Bag 20 0.25 8 180 450 No. 1 bag filter

No. 2 Bag 40 0.5 17 180 810 No. 2 bag filter

No. 3 Bag 60.09 1.3 108 230 No. 3 bag filter

No. 4 Bag 12 0.16 2.3 108 380 NO.4 Bag Filte

The non-deformable monofilament wire is woven into a net according to a specific pattern. The joints of the filament wire are welded tightly to increase the strength,

and the filter grade can reach absolute precision. It is suitable for the high precision requirements in the industries of paint, ink, resin and paint.

First of all, nylon is developed by Carothers, an outstanding scientist in the United States, and a research team under his leadership. It is the first synthetic fiber in the world. Nylon is a term for polyamide fibers.

The appearance of nylon has brought a new look to textiles. Its synthesis is a major breakthrough in synthetic fiber industry and a very important milestone in polymer chemistry.

The nylon used in nylon filter bags has good comprehensive properties, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication, and low friction coefficient.

It has certain flame retardancy and is easy to process. It is suitable for filling and reinforcing with glass fibers and other fillers to improve performance and expand application scope.

In addition, nylon filter bags have good cleaning and anti-fouling properties, which are affected by the cross-section shape of the fibers and the anti-fouling treatment of the back passage.

The strength and hardness of nylon fibers have little effect on cleaning and anti-fouling.

We're looking back at nylon filter bags.

Nylon filter bags are made of high strength nylon woven mesh sewing, and all of them adopt unique edge-wrapping technology to prevent needle hole leakage to the greatest extent,

and retain impurities larger than their own mesh directly on the surface of the material.

Particles smaller than the mesh diameter enter the downstream through the mesh, so nylon monofilament filter bags achieve surface filtration, smooth surface is also easy to clean, can be used repeatedly.

The advantages of nylon filter bag are as follows:

1. High-speed industrial sewing machine without silicone oil cooling will not produce filter bags with silicone oil pollution.

2. The improved suture of nylon filter bag mouth has no high protuberance, which leads to side leak without needle eye and leads to side leak.

3. All the labels on nylon filter bags marked with product specifications and models are easy to remove, so as to prevent the pollution of filter bags by labels and ink in use.

4. The filter precision ranges from 0.5 micron to 300 micron. The material is divided into polyester, polypropylene nylon and other filter bags.

5. Argon arc welding technology for stainless steel and galvanized steel ring. The diameter error is only less than 0.5 mm and the horizontal error is less than 0.2 mm.

The filter bag made of this kind of steel ring can be installed in the equipment to improve the sealing degree and reduce the probability of side leakage.

Advantages of Nylon Filter Bag - Recommended Precision:

In food and beverage industry, 80 mesh to 350 mesh nylon filter bags are recommended; in chemical industry, 80 mesh to 150 mesh nylon filter bags are recommended.

Nylon Filter Bag - Size Specification:

Size Name of Filter Bag Maximum Flow (Water) m3/h Filtration Area () Volume (L) Diameter mm Length mm Matching Filter Name

No.1 Bag 20 0.25 8 180 450 No. 1 bag filter

No. 2 Bag 40 0.5 17 180 810 No. 2 bag filter

No. 3 Bag 60.09 1.3 108 230 No. 3 bag filter

No. 4 Bag 12 0.16 2.3 108 380 NO.4 Bag Filte

The non-deformable monofilament wire is woven into a net according to a specific pattern. The joints of the filament wire are welded tightly to increase the strength,

and the filter grade can reach absolute precision. It is suitable for the high precision requirements in the industries of paint, ink, resin and paint.

![INDUSTRY NEWS [field:typename/]](../../picture/new-banner.jpg)