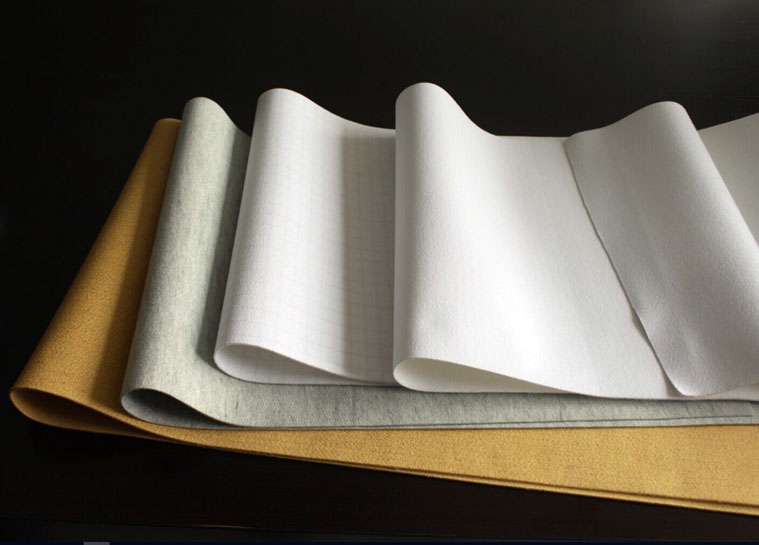

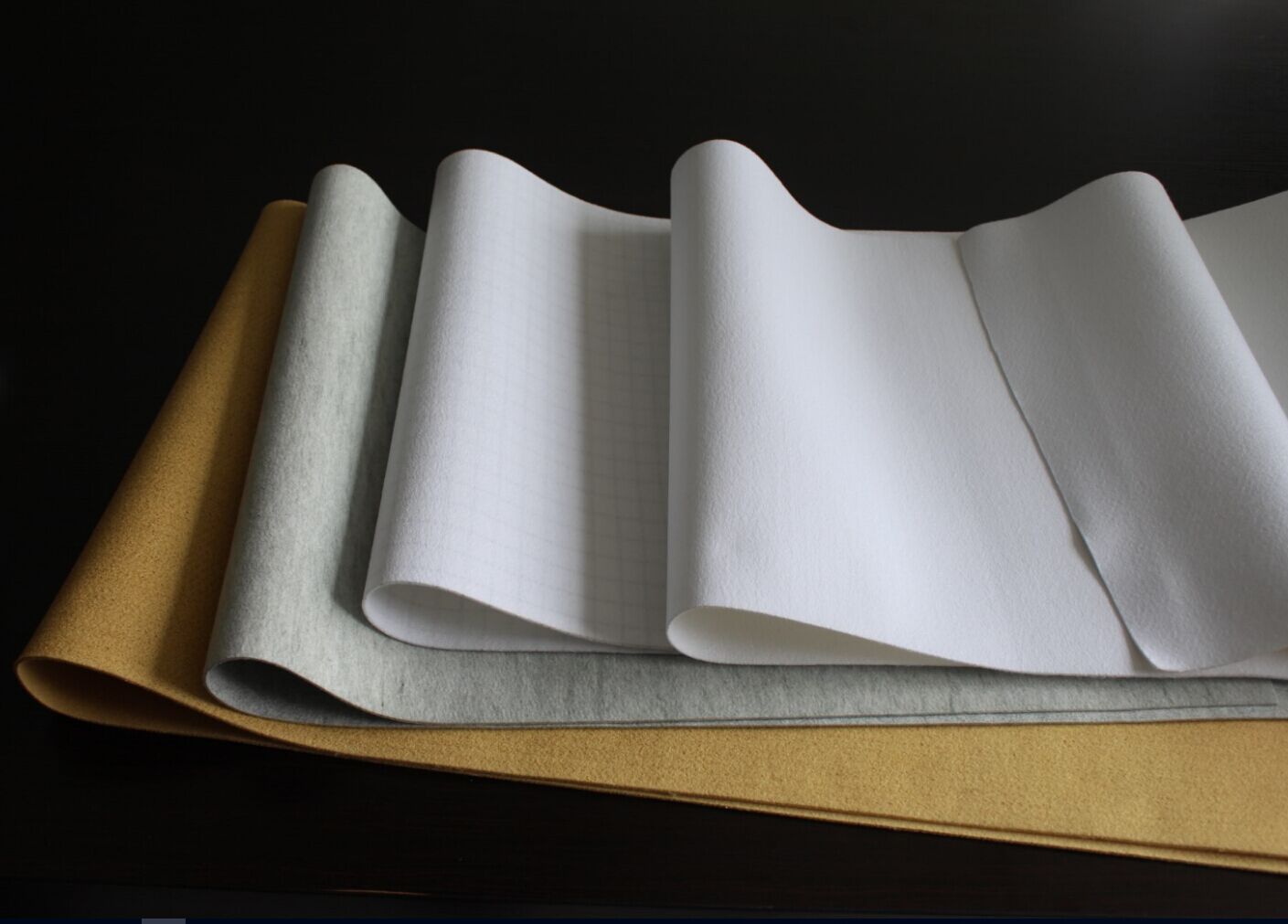

The Normal Temperature Needle Punched Felt

When mentioned the working condition at the temp 90~130 degree,it would choice the material of Polyester needled felt, polypropylene needled felt, Acrylic (homopolymer material) needle punched felt. And according to the different requirement of the different working operation, the material surface treatment could be done as singeing, calendering, oil and water proof, PTFE impregnation, coating and laminating process...INTRODUCTION:

-

The Normal Temperature Needle Punched Felt

Features

● The normal temperature needle punched felt have moderate temperature- resistance.

● It is effective normal temperature filter material.

● Good air premeability, great twist- resistance weariable, and effective dust-cleaning performance.

● Widely used in the field of steel, cement, chemical industry, food processing and pharmaceutical manufacturing, etc.

Specifications

|

The Normal Temperature Needle Punched Felt |

|||||||

|

Name |

Weight |

Thickness |

Air permeability (m3/m2.min) |

Working Temperature(℃) |

Thermal Shrinkage |

||

|

Continuous |

Peak |

Warp |

Weft |

||||

|

Polyester needle punched felt |

400-700 |

1.7-2.6 |

8-20 |

130 |

150 |

≤1 |

≤1.5 |

|

Polypropylene needle punched felt |

400-700 |

1.7-2.6 |

8-20 |

90 |

110 |

≤1 |

≤1.5 |

|

Acrylic needle punched felt |

500-600 |

1.8-2.2 |

8-20 |

125 |

150 |

≤1 |

≤1.5 |

|

PTFE membrane needle punched felt |

400-600 |

1.7-2.5 |

3.6-5 |

120 |

150 |

≤1 |

≤1.5 |

*** We have ability to use all kinds of manufacturing methods of non-woven fabric,

combining with fibers’ specialties to design products that fit requirement of customers ***

Applications

|

Dust filter media |

PH Value |

Application |

Remark |

|

|

4~12 |

Applicable to mine, limestone, cement, |

Good resistance to oxidation, while limited resistance |

|

Polypropylene (PP) |

1~14 |

Applicable to food,flour,sugar,fertilizer, |

|

|

|

3~11 |

Applicable to detergent,waster incineration, |

Good resistance to hydrolysis. |

NXT : 下一篇:High Temperature Needle Punched Felt

PRE : 上一篇:Woven Fiberglass filter media

![[field:typename/]](../../picture/prod-banner.jpg)